We will reply you within 12 hours in working day.

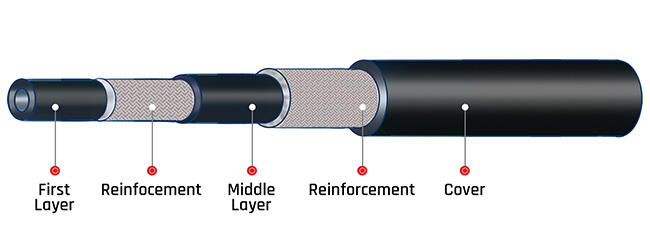

Product Structure Diagram

Product Introduction

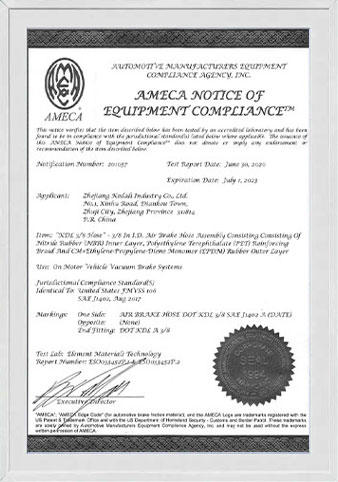

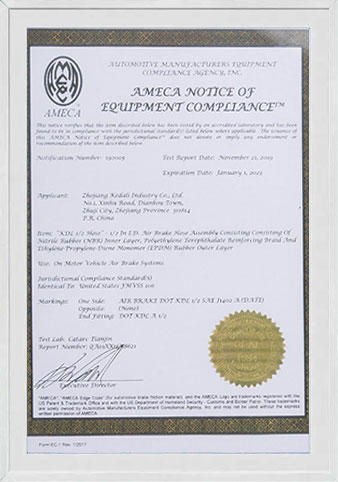

- Standard SAEJ1401

- Excellent durability

- Low expansion

- Good pulse performance

- Excellent weather resistance

| Number | I.D. mm | 0. D. mm | Wall Thickness. mm | Wall Diff Max. mm | Expansion ml/Max. mm | Burst Pressure Min. MPa | |

| 6.9MPa | 10.3MPa | ||||||

| 1 | 3.3+0.2-0.1 | 10.5+0.2-0.1 | 3.65 | ≤0.25 | <1.08 | <1.38 | >70 |

| 2 | 4.8±0.2 | 13 ±0. 3 | 4.35 | ≤0.3 | <1.81 | <2.36 | >60 |

| 3 | 6.3±0.2 | 15 ±0. 3 | 3.75 | ≤0.3 | <2.69 | <3.84 | >50 |

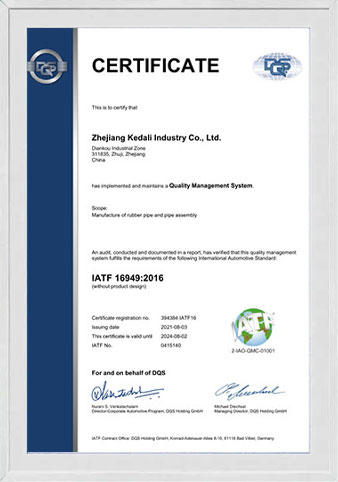

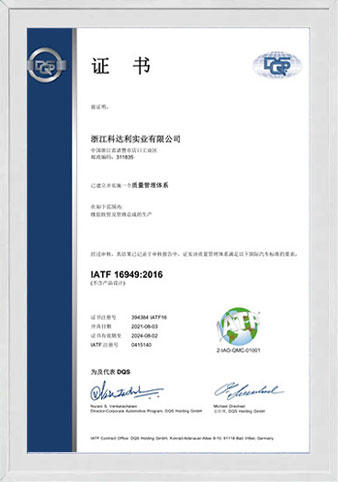

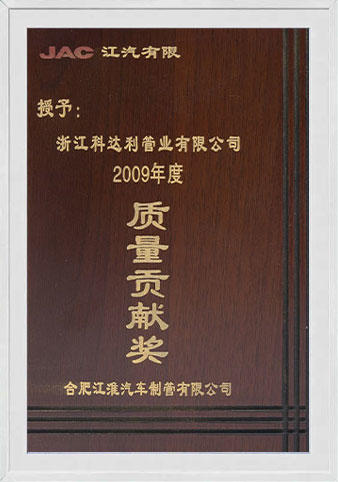

Zhejiang Kedali Industrial Co., Ltd. is committed to the R&D, production and sales of vehicle air condition hoses, hydraulic brake hoses, pneumatic brake hoses, adblue pipes, oil cooling pipes, power steering hoses, water pipes, oil pipes, vacuum brake hoses and tube assembly. As China Hydraulic Brake Hose manufacturers, With highly automated production capacity and rich management experience, the company has the ability to produce 40 million meters of various rubber hoses and 5 million sets of assemblies annually. With modern equipment and three-dimensional storage system, it can accommodate products pieces, better control the quality, ensure the inventory and timely delivery. As a well-known OEM Hydraulic Brake Hose factory, Kedali advocates the belief of “pursuit of excellence, integrity based”, takes the national model brand and industry product benchmark as its mission, and is dedicated to providing our partners with safe, reliable, cost-effective products and quality services.

The company has the internationally advanced production technology and equipment for automotive rubber hoses, and has jointly developed new products with many well-known research institutions and testing centers in China. In order to meet the needs of the continuous development of the automobile industry and the development of new technologies and products, the company has set up a research and development center and a product testing and testing center

The development of air pressure brake hose technology is being driven by a multitude of innovative advancements aimed at enhancing the efficiency, rel...

Air pressure brake hoses are indeed designed to withstand wear and corrosion, even when exposed to harsh environmental conditions. These hoses serve a...

Pre-shaped hoses offer a promising solution to simplify complex hydraulic configurations, streamlining operations and enhancing efficiency across vari...

Air pressure brake hoses are critical components of a vehicle's braking system, tasked with the vital role of preventing brake fluid leakage and conta...

The design of air pressure brake hoses plays a pivotal role in determining the effectiveness and reliability of a vehicle's braking system. These hose...

Heater hoses are engineered to withstand a wide range of temperatures and pressure conditions encountered within automotive cooling systems. As critic...